The Lauber L-ENZ drying system is a compact and complete solution for the bulk drying of biomass fuels. Essentially the L-ENZ unit comprises of an air intake system, frequency modulated fan unit, high efficiency heat exchanger and sophisticated controls system to maximise electrical and thermal efficiency of the process dependent on the material being dried, the heat available and the target drying time.

The L-ENZ unit comes complete with its own waterproof housing as a stand alone building that can live outside, the housing is complete with pitched roof and gutter along with both lifting eyes and forklift pockets at the base. In come instances (for example with CHP’s, AD plants or areas with process heat available), the L-ENZ can be supplied as a skid mounted unit to be housed indoors allowing warm process heat to be utilised as a means of ‘pre-heating’ the air, this often replaces the need for ventilation and lowers the thermal demand via hot water thus increasing the overall efficiency of the system and fulfilling two functions; cooling of the room and drying of biomass fuel.

The L-ENZ 650 can be connected to either a series of purpose build drying bins, or a static drying floor or in some cases a combination of both. The L-ENZ receives its heat inout via a flow and return pipe and efficiently converts the heat from hot water into hot air and driving this hot air through the biomass material at a pressure dependent on both the type and quantity of material being dried.

The L-ENZ 650 (18.5kw) is suitable for drying up to:

6 drying bins (or equivalent area of drying floor) of woodchip

or

12 drying bins (or equivalent area of drying floor) of firewood logs

The L-ENZ 650 (22kw fan) is suitable for drying up to:

7 drying bin (or equivalent area of drying floor) of woodchip

or

14 drying bins (or equivalent area of drying floor) of firewood logs

Fan : With the L-ENZ 650 it is possible to choose between a 18.5kw or a 22kw fan for your unit.

Air temperature control: This optional operating mode allows the outgoing air temperature to be regulated to a set point, particularily useful if drying a temperature sensitive material such as grain.

Pressure differential control: This optional operating mode allows the fan to self regulate based on the type and quantity of fuel being dried.

Heat Meter : The L-ENZ can be factory fitted with a QP40 class 2 heat meter to ensure RHI compliance.

Water flow regulation: The L-ENZ 650 can be supplied either with a frequency modulated pump or a 3 way mixer valve depending on your application.

Valves: We offer the option to intergrate 4 stop cocks into the system either side of the pump to allow for isolation from the heat input pipework if required, this option also comes with a sediment trap if chosen.

Inlet pipe positions: As standard the L-ENZ unit has the flow and return pipes exiting/entering at the top corner adjacent to the air intake, however if you prefer we can an no extra charge allow the pipes to enter through a floor hatch internally.

Antifreeze: If specified it it possible to add antifreeze to the system up to 25% giving a frost protection down to -9 degrees, however we need to know in advance if this is your intention to specify both the pump and heat meter accordingly

Sound reduction: It is possible to have both a 10dB or a 20dB silencer added to your L-ENZ unit if you intend to operate in a particularly noise sensitive area. Its also possible through the controls to lower the fan speed at night or at set times to decrease noise as standard.

Number of adjustable air outlets: This L-ENZ 650 unit is supplied with only supplied in conjunction with a solid duct system, please contact us to establish the best ducting system for your specific application.

Housing: complete weatherproof aluminium housing or skid mounted

Fan: high performance radial fan mounted in solid steel housing. Finished to RAL 3003 and IE2 compliant for optimised energy efficiency

Heat Exchanger: Supplied with an appropriately sized large Copper/Aluminium water to air heat exchanger. The maximum possible thermal conversion depends on the operating conditions and ambient air temperature.

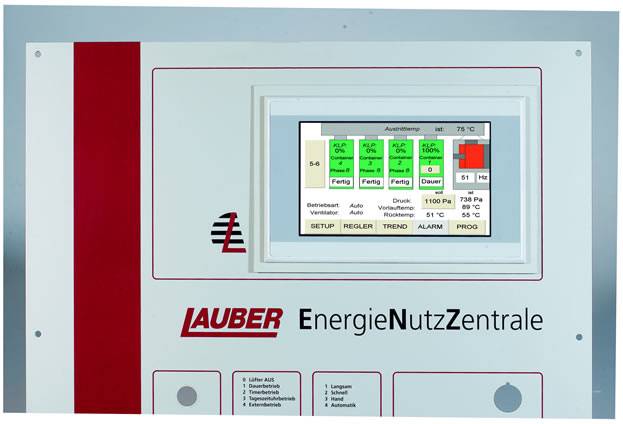

Control system: Supplied with touch screen controls

Electrical efficiency: On average electrical consumption is approximately 3-4kwhrs per cubic meter of fuel dried.

Heat output (kW): 555-840

Thermal output:

- 840.0 @0°C

- 745.0 @10°C

- 650.0 @20°C

- 555.0 @30°C

Fan size (kW): 18.50

Controls: Touch screen

Drying performance (capacity/days):

Woodchip: 190 – 220m3 / 1-2 days

Logs: 380 – 440m3 / 5-10 days